Thursday, October 25, 2007

Clearing Range Rover ECU fault codes

Clearing Fault Codes

1. Switch ignition on.

2. Disconnect serial link mating plug, wait 5 seconds, then reconnect.

3. Switch ignition off, wait for main relay to drop out.

4. Switch ignition on. The display should now be reset. If there are other faults, the next one will be displayed. Otherwise the display will be black.

5. If there is more than one fault repeat steps 1 to 4, to clear each fault until the display is blank.

Link to more detailed pdf.

Sunday, October 21, 2007

Discovery windshield washer leaking

| VALVE - NON-RETURN WINDOW WASHER Item: AMR6676 | $3.49 | |

| Fits: Range Rover Classic | '87 - '95 Discovery I | '94 - '99 Range Rover 4.0 | '95 - '02 | ||

Saturday, October 20, 2007

New Ceiling Fan

Discovery tail light out again

Now all right side rear running lights are on, and installing the new fuse also resulted in the lights-on-but-keys-out-of-the-ignition beeper working again.

Also, the dash lights are now working again!

However, the light behind the clock is still not working, so perhaps that is the bulb for the clock being burned out.

Thursday, October 18, 2007

MS Word won't paste in reading layout

Setting the views back to print layout fixes this problem - the pasted text appears, not just paragraph marks.

Lousy MS products...

Wednesday, October 17, 2007

Blogger failing to honor exif orientation tags

Saturday, October 13, 2007

Bosch Dishwasher Repair SHU43C SHU43C05

The Cliff's Notes version of this project: the dishwasher had become very loud when washing, with a significant squeal factor. I ordered an impeller kit (see below) for the pump from PartsTap.com (thanks!) and installed it, which solved the problem. Removal & rebuilding of the pump requires pulling the dishwasher out from under the cabinet, turning it upside down, fixing the pump, and then reinstalling. It probably took me 3 1/2 hours, but I didn't know what I was doing and made a few missteps, taking apart stuff that didn't need to be.

The impeller kit order, from PartsTap.com you can email them at: customerservice **at** partstap.com

I received the shipment 3 or 4 days after ordering it.

Part Number Description Qty Price

---------------------------------------------------------------------------

PT8407128 (167085) Circulation pump repair kit 1 $67.48

-------------------------------------------------------------------------------

Subtotal $67.48

Tax $0.00

Shipping $5.95

Total $73.43

Now, details:

A digital camera is a great help for ensuring that you know how it all goes back together!

Also note in this picture, towards the left-hand side, the debris left by the leaking pump. The pillar next to that debris is where one of the rubber motor mounts hooks on - more about that below.

Note that nothing on the inside of the dishwasher needs to be removed for this procedure. I figured that out only after completely removing the whole pump assembly from the bottom of the wash tub.

I don't have any images or video of the pump seal being removed from the backing plate. Be careful with that procedure - work the old pump seal out of the backing plate by gently pushing it out from the motor side using a small screwdriver or similar. Work you way around and around to ease it out - don't try to do it all at once.

When installing the new seal, I cleaned the backing plate thoroughly then used a very small amount of Pam on the surface of the backing plate where the seal slides in. Always, be very careful not to damage the smooth carbon face of the seal, and keep it clean (no lubricant, grit, etc.).

This video shows the pump after the impeller has been removed. You can see the old seal still in place in the backing plate, and the o-ring around the perimeter of the backing plate. Also, you can see that the backing plate has non-equal lugs or ears, so that it only mates to the pump motor in one way.

In this picture, there is still a seal 0r guide remaining on the motor shaft - that slides right off. A replacement was included in my impeller kit.

Note that the impeller-to-seal interface should not be lubricated. The seal is a carbon seal that runs on a matching face of the impeller (a ceramic face?).

Friday, October 12, 2007

Comments are moderated

If you have any questions regarding the trucks listed for sale on this page, please email me at jbeale insert_at_symbol_here hevanet insert_period_here com.

Driving Theory first entry

Red light realignment - how cars change lanes as they approach a red light, in order to get ahead once the light turns green

Squirt - when a lane begins braking/compressing, but an adjacent lane is not braking, a car is likely to squirt from the braking lane into the adjacent lane

Compression - a lane that is densely occupied by cars and that is running next to an adjacent, less densely occupied lane is likely to squirt cars when the lane compresses (i.e., when traffic slows)

Panic - a reaction

Fear

Automoton - speeds up and slows down based only on what another car is doing. Driving alongside, tend to sit in your blindspot.

Blind spot - danger zone. Even if the driver does look for you, if you're in the blind spot, you won't be seen.

Lane changes - one of the most dangerous acts you face in heavy traffic is when cars in adjacent lanes change lanes. The space left-right is often far less than the space ahead and behind you. So, when a car changes lanes, you may not have much time to react.

Acceleration - a major advantage you have over cars

Braking - a major advantage you have over cars

"Pushing" the car ahead - riding behind a car, close enough that the car is encouraged to move along, but not so close that you discract and/or piss off the driver. If you're too far back, the car isn't thinking about you.

Head turn - drivers checking mirrors, blind spots in anticipation of changing lanes.

Signalling -

Telegraphing

Ambiguity - e.g., a car driving with its turn signal on for a mile - if you think he's not going to change lanes, he may do it. If you think he's going to change lanes, he probably never will.

Drift - car tracking to one side or the other of the lane, driving brail, etc.

Distraction - kids, cell phones, you, cops, accidents,

Riding the fender - safest place in heavy traffic - ride alongside the front fender of the car next to you - he can't possibly miss seeing you, right?

Link: Can't add gas to tank

Posted at LandRoverforums.com: http://www.landroverforums.com/m_21434/tm.htm

Hi all,

Just picked up a 1998 discovery, was at the gas station and I was not able to add gas.

It was almost on empty, light was on, but when I was filling up, the pump will stop like it was full and I was topping off. air was coming out of the fill hole, I had to add about 1/4 to 1/3 gallon, stop and try again, was able to get 3 gallons in before I gave up, enough to continue my trip

any ideas???

many thanks

Sounds like one of the vent lines is not allowing the tank to breathe. You are going to need to have some check all the fuel filler lines and vent to find the cause.

By chance you might also want to try another fuel pump, some gas stations have warn out filler handles and they just shut off early.

I tried 2 different pumps, and someone got to the first pump Iwas using, and he had no trouble

I am going to see if I can check the vent lines

thanks

might want to check to see if the fuel gauge is faulty and reading empty instead of full?? just a thought

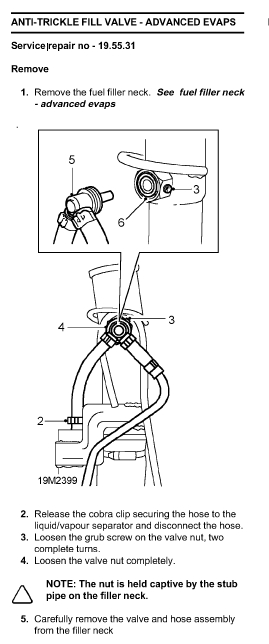

EVAPS, fuel tank, anti trickle fill valve

A posting quoting the Discovery Workshop manual's description of the anti-trickle fill valve. Could this valve's malfunction prevent filling the tank?

...from the Workshop manual...

A vent line flow restrictor known as an anti-trickle fill valve is fitted to the filler pipe in the line between the tank and EVAP canister. The function of this valve is to prevent overfilling the tank by trickling fuel in, thereby preserving the vapour space in the tank to allow for fuel expansion during hot weather.

The valve achieves this by blocking the vent line during the fuel filling process. The valve is operated by the action of inserting the filler gun so that when the fuel in the tank reaches the level of the filling breather, flow cut off occurs due to fuel filling the filler pipe.

Fuel level sensor

The fuel level sensor (fuel gauge sensor) on the Discovery died (symptom: fuel guage reads absolutely empty, yellow "low fuel" light on). The sensor works by varying resistance with the level of the float, low resistance at full tank and high resistance (something like 250 ohms) at empty tank. In the picture below, the arm extending to the lower left is the float arm, and attached to it you can see the wiper of the variable resistor. Note the small wire extending down across the front face of the wiper arm, which had rotted and broken so that the circuit was open. The open circuit made the fuel gauge read empty.

I fixed the sender, for now anyway, using a thin piece of copper wire I obtained by sacrificing a pair of headphones. Now, when the tank is absolutely full, the fuel gauge needle is about 1/2 a needle width above the full line.

Note that, when testing the sensor with the pump installed in the tank, the green/black and black wires lead to the sensor. However, since there are two black wires (ground), one for the sensor and one for the pump motor, and because these ground wires are not common, i.e., not tied together, within the pump, you need to check the correct black wire. On this pump, looking at the 4-pin multiplug socket from the top, with the wiring harness disconnected, the correct black wire is the one adjacent side-to-side, not top-to-bottom (where "top" is where the latch on the harness connector is, towards the front of the car).

Fuel filler neck part no, $

Link: '98 Disco (US) fuel filler neck problem link

Posted on May 14, 2001 at http://www.landroverexchange.com/forum/messages/11991.html

Prior to the recall notice last year, I was having problems filling the gas tank. About the first 5-6 gallons went in just fine, then the remaining 10-15 gallons took forever to get into the tank. The gas would constantly fill up to the rim of the filler neck, then you waited a few seconds, then pumped another 1/4 gallon or so, then waited........

The tank filled just fine after the recall notice work was done last September, but last week, started again.

Link: 2001 Discovery fuel filling problem

Posted at: http://en.allexperts.com/q/Land-Rover-Repair-1470/Fueling.htm

Expert: John McInnis

Date: 7/17/2005

Subject: Fueling up

Question

I have a 2001 disco2 4.0 litre v8 when trying to fill the gas tank the gas backs up in the filler neck and shuts off the filler nozzle it does this even when filling slowly by hand i cannot even fill by locking the nozzle i must do this by hand

i have the NAS filler neck this is a really annoying is there a modification that can be done to the filler neck or a replacement neck

any info on this will be greatly appreciated

thanks bruce

Answer

Hi Bruce,

I've heard of this problem before. It has to be a pressurization problem. There is an air vent tube that allows air to pass as you are filling your tank. If this tube is crimped or damaged it could restrict the air flow and thus cause this problem with every fill-up.

One owner who had this problem, while under warranty, was so fustrated after at least 4 service calls that he insisted on having his fuel tank replaced. Seems to have solved the problem for him.

In your case, you may have to replace the filler neck assembly, perhaps the fault lies near the top and not within the tank. Otherwise, the tank will have to be replaced.

I wondered if the air vent tube could be tested...but since it deals with gas, I'd have an expert pressure test this for blockage.

Best of luck,

JohnMc

Link: 1999 Discovery fuel filling problem

Posted at: http://www.motorbeat.com/complaint/412653/

Complaint for Land Rover Discovery 1999

Complaint about FUEL SYSTEM, GASOLINE : STORAGE : TANK ASSEMBLY : FILLER PIPE AND CAP

Consumer Complaint:

CONSUMER NOTICED WHEN THE OUTSIDE TEMPERATURE IS HOT GASOLINE FILLER NECK DOES NOT ALLOW YOU TO PUT MORE THAN 2 GALLONS. DEALER NOTIFIED. *AK

Date of Incident:

20030710

Tried something new

I tried filling the Discovery's tank with the small pig-tail vent line disconnected, but the problem persisted. The line is easily detached (quick connect) when looking up at the tank underside kneeling down next to the fuel filler door.

Since disconnecting the line made no difference, it appears that the problem is with getting the fuel down the filler neck, rather than getting vapors out of the tank.

Labels

- Angry Birds (1)

- iPhone (1)

- sms (1)

- tag_apple (1)

- tag_automotive (29)

- tag_bosch (1)

- tag_craigslist (3)

- tag_discovery (11)

- tag_dishwasher (1)

- tag_dog (2)

- tag_dog_wash (2)

- tag_harley (2)

- tag_land_rover (15)

- tag_microsoft (1)

- tag_microsoft_word (1)

- tag_os_x (1)

- tag_repair (31)

- tag_s60 (2)

- tag_skype (1)

- tag_trailer (1)

- tag_v70 (11)

- tag_volvo (12)

- text message (1)